Specifications

For additional information, please contact the sales department or one of our sales representatives.

Blower

A 5 HP blower rated at 850 – 1150 CFM is standard while a 7.5 blower rated at 1000 – 1600 CFM is optional at extra cost. Fan motors are included. Left-hand fan mount facing the Chesaw control cabinet is the standard configuration. This 5hp blower does have the recirculation “air assist” feature spelled out on the options page (blower upgrade). Due to the small size of this Chesaw, the 7.5 HP upgrade is not practical.

Screen Size

3/8”

Safety Package

Emergency Stop switching. Locking electrical cabinet. Appropriate warning signage. Interlocking Tilt Chutes for safe, quick access to cutting chamber. This feature aids in safely accessing the internals of the mechanism to clear possible jams. (This was formally an option, but has been now incorporated into the Chesaw reflecting increase in the base unit pricing.)

Lubrication

Oil bath lubrication on covered knife spur drive gears for single speed knife sets. Automated bearing lubrication for all drive bearings can be provided via an optional Lincoln Lube “QLS 301” programmable system with alarm both audible and visible (strobe light). This is an up-grade option.

Electrical Control System

480 volt AC, 60 HZ, 3Ø, with a 60 amp circuit breaker

Machine Dimensions

Overall length “in-line direction” is 53” inches. (1346mm) Overall width “cross machine direction” is 94.6” inches. (2403mm) Overall height is 45.8” inches. (1163mm) with cabinet attached Overall height is 28” to 36” inches. (711 - 914mm) with cabinet remotely mounted to frame of the GN Thermoformer. The height of the infeed chute must be specified at time of ordering this model Chesaw.

Maximum Sheet Width

33.5 inches (851mm) – A special infeed

chute would have to be fabricated to accommodate wider web (up to 35”

width – 889mm)

In Feed Drive

• Siemens MM’4 440/3 3 HP “Vector” drive, 380- 480 Volt AC, 50/60 HZ, 3 Ø mounted in control cabinet. Higher HP ratings are optimally available as an upgrade (5 HP).

• An Allen Bradley Vector Drive is also available as an optional upgrade for the

HP specified.

In Feed Unit Motor

• Baldor 3 HP “Inverter duty” encoderless motor with optional cooling blower (120v). This motor can optionally be upgraded for heavy gauge sheet applications with high throughput requirements.

• A Reliance equivalent motor is available

as an up-charge/upgrade.

In Feed Unit Gear Reduction

56:1 Ratio Worm Reduction “C” series

shaft mounted David Brown gearbox is herein provided. Upgrade larger gearbox

and motor are available on the options

page.

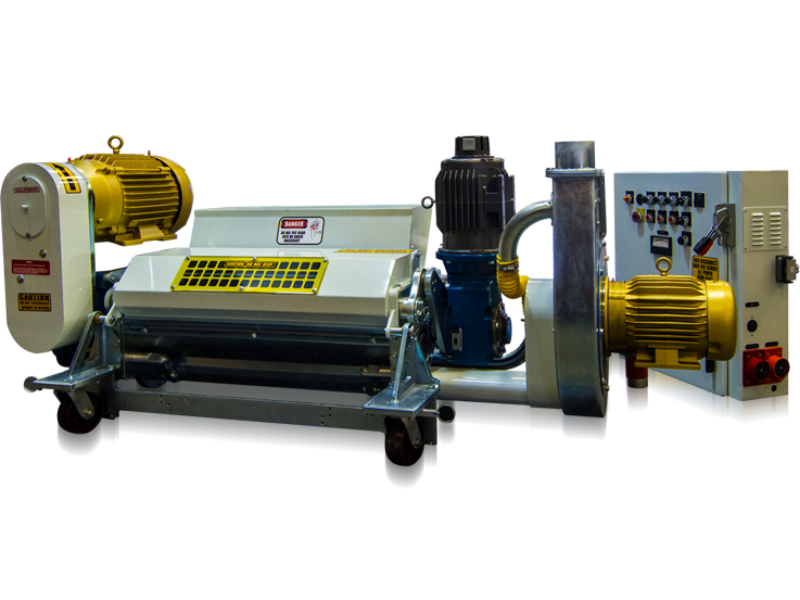

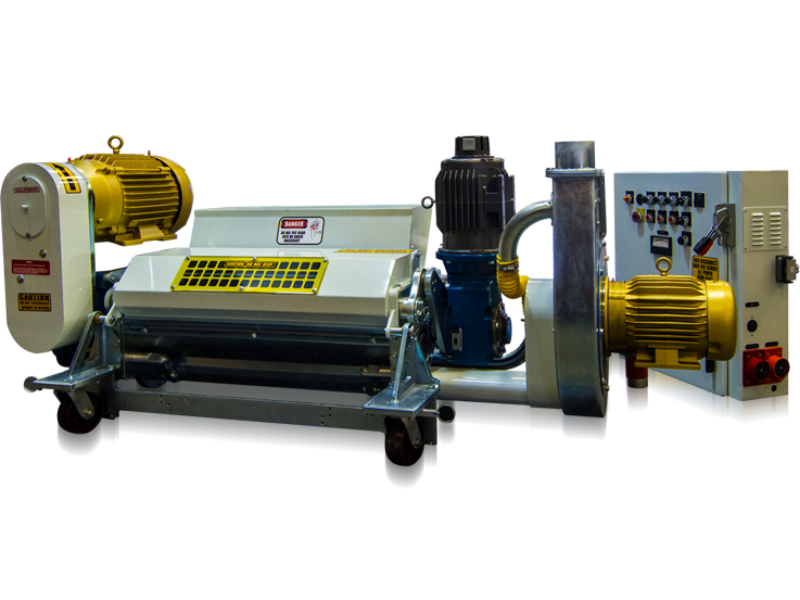

Chesaw Cutting Unit

Two rows of 66 each helically stacked

multi-toothed aggressive profile ¼” width self-sharpening slitting knives are provided. This cutting arrangement is a scaled

version of our larger Chesaw cutting

mechanisms. Various helical staked

patterns are employed in the layout to

evenly distribute material for cutting while keeping oversized materials and web tracking to the center of the Chesaw

cutting chamber.

Fully Adjustable Scraper Mechanism

The scraper plate mechanism incorporates side adjustment bolts and dowel pin

locators for infinitely variable positions

and spacer to scraper clearance for

optimal cleanout during reduction of different gauges of plastic.

Chesaw ‘Cutting Stack’ Drive

Baldor 15 HP AC induction motor with a 36:48 belt drive reduction through a 10:1 ratio series 40-style shaft mounted “Cone Drive” fan cooled gearbox provides the cutting power.

Maximum Sheet Width

33.5 inches (851mm) – A special infeed chute would have to be fabricated to accommodate wider web (up to 35” width – 889mm)

In Feed Drive

• Siemens MM’4 440/3 3 HP “Vector” drive, 380- 480 Volt AC, 50/60 HZ, 3 Ø mounted in control cabinet. Higher HP ratings are optimally available as an upgrade (5 HP).

• An Allen Bradley Vector Drive is also available as an optional upgrade for the HP specified.

In Feed Unit Motor

• Baldor 3 HP “Inverter duty” encoderless motor with optional cooling blower (120v). This motor can optionally be upgraded for heavy gauge sheet applications with high throughput requirements.

• A Reliance equivalent motor is available as an up-charge/upgrade.

In Feed Unit Gear Reduction

56:1 Ratio Worm Reduction “C” series shaft mounted David Brown gearbox is herein provided. Upgrade larger gearbox and motor are available on the options page.

Chesaw Cutting Unit

Two rows of 66 each helically stacked multi-toothed aggressive profile ¼” width self-sharpening slitting knives are provided. This cutting arrangement is a scaled version of our larger Chesaw cutting

mechanisms. Various helical staked patterns are employed in the layout to evenly distribute material for cutting while keeping oversized materials and web tracking to the center of the Chesaw cutting chamber.

Fully Adjustable Scraper Mechanism

The scraper plate mechanism incorporates side adjustment bolts and dowel pin locators for infinitely variable positions and spacer to scraper clearance for optimal cleanout during reduction of different gauges of plastic.

Chesaw ‘Cutting Stack’ Drive

Baldor 15 HP AC induction motor with a 36:48 belt drive reduction through a 10:1 ratio series 40-style shaft mounted “Cone Drive” fan cooled gearbox provides the cutting power.

Blower

A 5 HP blower rated at 850 – 1150 CFM is standard while a 7.5 blower rated at 1000 – 1600 CFM is optional at extra cost. Fan motors are included. Left-hand fan mount facing the Chesaw control cabinet is the standard configuration. This 5hp blower does have the recirculation “air assist” feature spelled out on the options page (blower upgrade). Due to the small size of this Chesaw, the 7.5 HP upgrade is not practical.

Screen Size

3/8”

Safety Package

Emergency Stop switching. Locking electrical cabinet. Appropriate warning signage. Interlocking Tilt Chutes for safe, quick access to cutting chamber. This feature aids in safely accessing the internals of the mechanism to clear possible jams. (This was formally an option, but has been now incorporated into the Chesaw reflecting increase in the base unit pricing.)

Lubrication

Oil bath lubrication on covered knife spur drive gears for single speed knife sets. Automated bearing lubrication for all drive bearings can be provided via an optional Lincoln Lube “QLS 301” programmable system with alarm both audible and visible (strobe light). This is an up-grade option.

Electrical Control System

480 volt AC, 60 HZ, 3Ø, with a 60 amp circuit breaker

Machine Dimensions

Overall length “in-line direction” is 53” inches. (1346mm) Overall width “cross machine direction” is 94.6” inches. (2403mm) Overall height is 45.8” inches. (1163mm) with cabinet attached Overall height is 28” to 36” inches. (711 - 914mm) with cabinet remotely mounted to frame of the GN Thermoformer. The height of the infeed chute must be specified at time of ordering this model Chesaw.