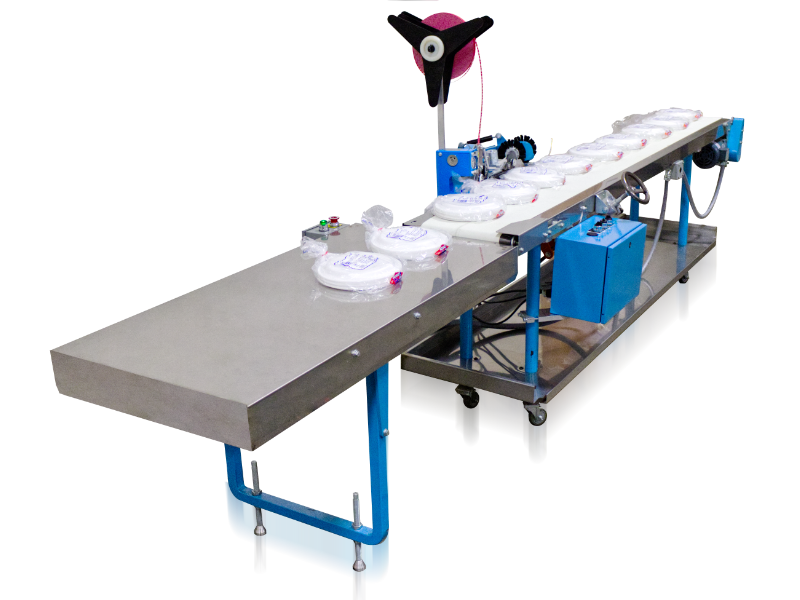

The MARK-60 bag closing system will bag 60 bags per minute using the Kwik Lok

style clip (Optional I-LOK Clip). This system has three components that are in line that are mounted to a conveyor.

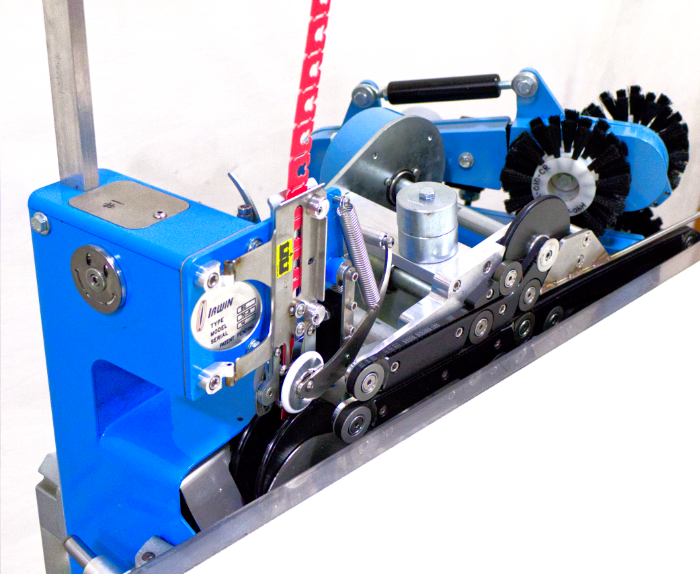

The second stage has a higher speed drive wheel top and bottom that gathers the length of the bag by about half. The third stage has an upper and lower belt that holds the gathered bag and transfers the neck of the bag to the clip for a better lock that holds the entire bag in the clip.

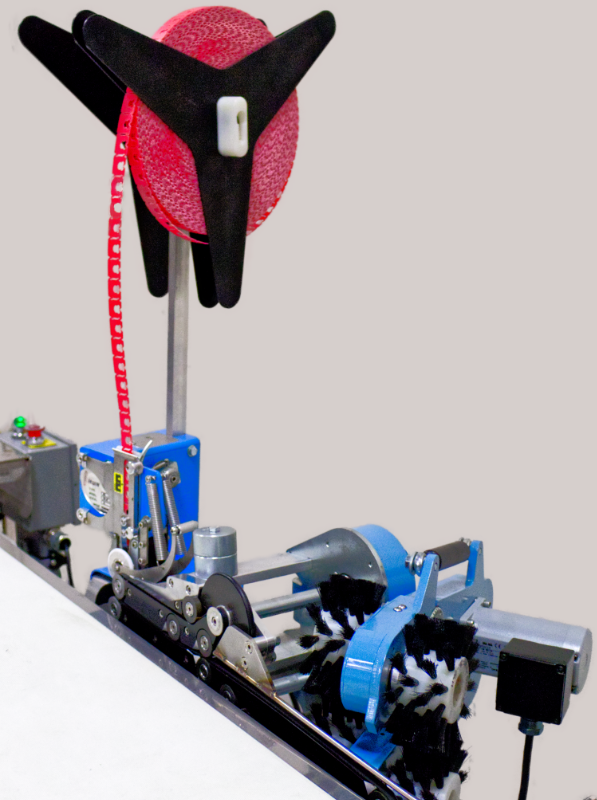

Third is the bag clip closer system that uses the Kwik Lok style clips (Optional I-LOK Clip) and has an easy access door with a magnetic closer lock. This helps operators on the production line to access the strip of clips in a simpler way without the need of tools. This reduces downtime.

We also provide an anti-stick drive system that eliminates the wrapping of the bags around the drive system. This has improved up time on the production floor and reduced maintenance of the unit.

Specifications

The MARK-60 bag closing system will bag 60 bags per minute using the Kwik Lok style clip (Optional I-LOK Clip). This system has three components that are in line that are mounted to a conveyor.

First in line is our new 4 brush system that helps align the bag with the product. It is the preferred brush system. Longer bristles are more forgiving, easier to set and enables the bags to flow freely without jams or misfeeds.

Second is the bag gathering system. The first stage uses a single lower belt that transfers the product to the second stage. The second stage has a higher speed drive wheel top and bottom that gathers the length of the bag by about half. The third stage has an upper and lower belt that holds the gathered bag and transfers the neck of the bag to the clip for a better lock that holds the entire bag in the clip.

For additional information, please contact the sales department or one of our sales representatives.

First in line is our new 4 brush system that helps align the bag with the product. It is the preferred brush system. Longer bristles are more forgiving, easier to set and enables the bags to flow freely without jams or misfeeds.

Second is the bag gathering system. The first stage uses a single lower belt that transfers the product to the second stage.

We can also provide a conveyor that has a height adjustment for the product stacks that you are running.

Third is the bag clip closer system that uses the Kwik Lok style clips (Optional I-LOK Clip) and has an easy access door with a magnetic closer lock. This helps operators on the production line to access the strip of clips in a simpler way without the need of tools. This reduces downtime.

We also provide an anti-stick drive system that eliminates the wrapping of the bags around the drive system. This has improved up time on the production floor and reduced maintenance of the unit.

We can also provide a conveyor that has a height adjustment for the product stacks that you are running.