Material Index

Chain Rail Type

50 Chain/Stainless body

Chain Rail Preheater

Optional

Sheet Stretch In Forming Area

52" Inch Tool .5" (51" Tool and Smaller 1.5")

(50.5" Tool and Smaller 2.0")

*Pneumatic operated to allow for sheet to heat up and

stretch, therefore allowing the chain rails to feed through

without stalling the drive in solid sheet.

Web Advance

140" Per Second

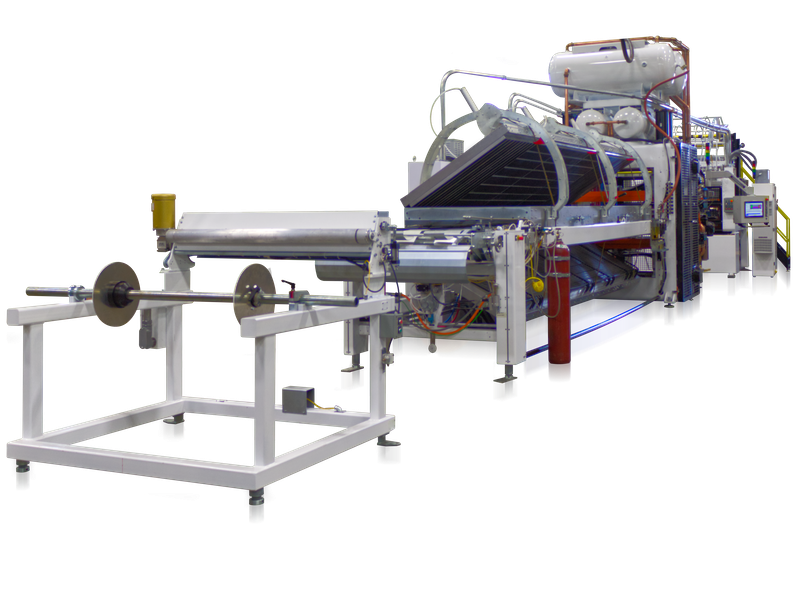

Thermoformer Specifications

Heat Tunnel

Length

230"

Heating Element

Quartz

Temperature Control

Standard Siemens S7-1500T Heat Control

Max Sheet Width

54"

Max Product Depth

7"

Max Sheet Gauge

.150

Max Tool Size

52" x 52"

Top Platen Travel

9"

Bottom Platen Travel

9"

Max Former Tonnage

125 TONS

Top Split

18"

Bottom Split

15"

Shut Height

33"

Servo Adjustable Shut Height

Max Stroke 3/8" Standard

Dry Cycle Time

54 cycles

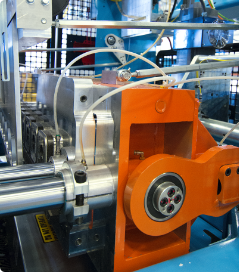

Platen Drive

Separate Servo Drives

Third Motion

Optional

Compressed Air Consumption

10 CFM@100 PSI Excluding Tooling Volume Needed

Electrical Service

480/380 V 50/60HZ

Former

Sheet Width

Max 52" Wide (1320.8mm), Min 30" (762mm)

Product Depth

7" (177.8mm) Maximum

Shut Height

13" Maximum

Auto Thread

Standard

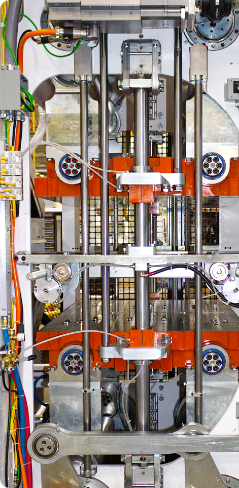

Trim Press Specifications

Stroke

10" (254mm) Maximum

Dry Cyrcle Speed

1-220 cpm

Servo Ejector

Optional

For additional information, please contact the sales department or one of our sales representatives.